Have you ever seen a product and thought,

“I came up with that years ago!”?

Well, that doesn’t have to happen anymore.

What if you wanted to publish your own book, develop a software application, or put your company logo on an existing product? Well, there are many platforms that allow you to do that in a single pipeline.

But what if you wanted to create your own product? How do you do that?

Development of a physical product is an expensive, complicated process.

You need to design it, fund it, manufacture it, warehouse it, sell it, and then fulfill and ship it to the customer.

Either you need to learn all these steps yourself, or you need to hire individual professionals to do the work for you.

What if a single company could perform all the tasks needed to bring your idea from napkin sketch to finished product?

CT3D is that company, and we’re announcing the Turnkey Manufacturing Platform. A place where any designer, product developer, influencer, or Maker can bring their ideas.

CT3D will handle the manufacturing backend using advanced design, hybrid manufacturing, and on-demand production.

CT3D focuses on three core issues with the current manufacturing industry.

The first issue is Environmental Impact. CT3D reduces the environmental impact of consumer products by designing the product for hybrid manufacturing and on-demand production.

The second issue is Access. CT3D provides turnkey manufacturing, which means that designers can focus on what they do best: designing cool consumer products. CT3D has a transparent pricing structure to go from idea to market, and the speed to market is faster than traditional product development.

The third issue is Amplification. CT3D provides a unified service platform that integrates design, manufacturing, and marketing in a single pipeline.

CT3D works with the designer to develop the product for placement on CT3D’s e-commerce platform.

CT3D handles the manufacturing of the product when it’s purchased, and then fulfills delivery of the product to the customer.

CT3D also works with influencers to market the product.

CT3D works with designers to bring their idea to life.

CT3D’s flexible factory has a catalog of generic hardware for the designer to use. The designer bases their design using these off-the-shelf components.

This reduces the complexity of the fabrication, allows for Design for Additive Manufacturing (DfAM) to maximize the strengths of additive manufacturing, reduces the cost per unit by using common components, and allows for streamlined fabrication and assembly.

CT3D’s flexible factory products the product locally, eliminating international logistics & warehousing.

Future franchising will allow the products to exist as a digital asset until purchased. Then the digital file can be forwarded to the CT3D location closest to the customer, reducing shipping costs.

A transparent and clear price-to-market allows designers to know what they’re getting into, and how much it’s going to cost. They can then plan accordingly to raise the needed funding.

Once development is complete, CT3D places the product on its e-commerce platform and only fabricates the product when a customer purchases it. The designer then gets a commission on each sale made.

This gives an incentive for the designer to bring their fans to the platform, thus increasing traffic and amplification.

CT3D’s business model

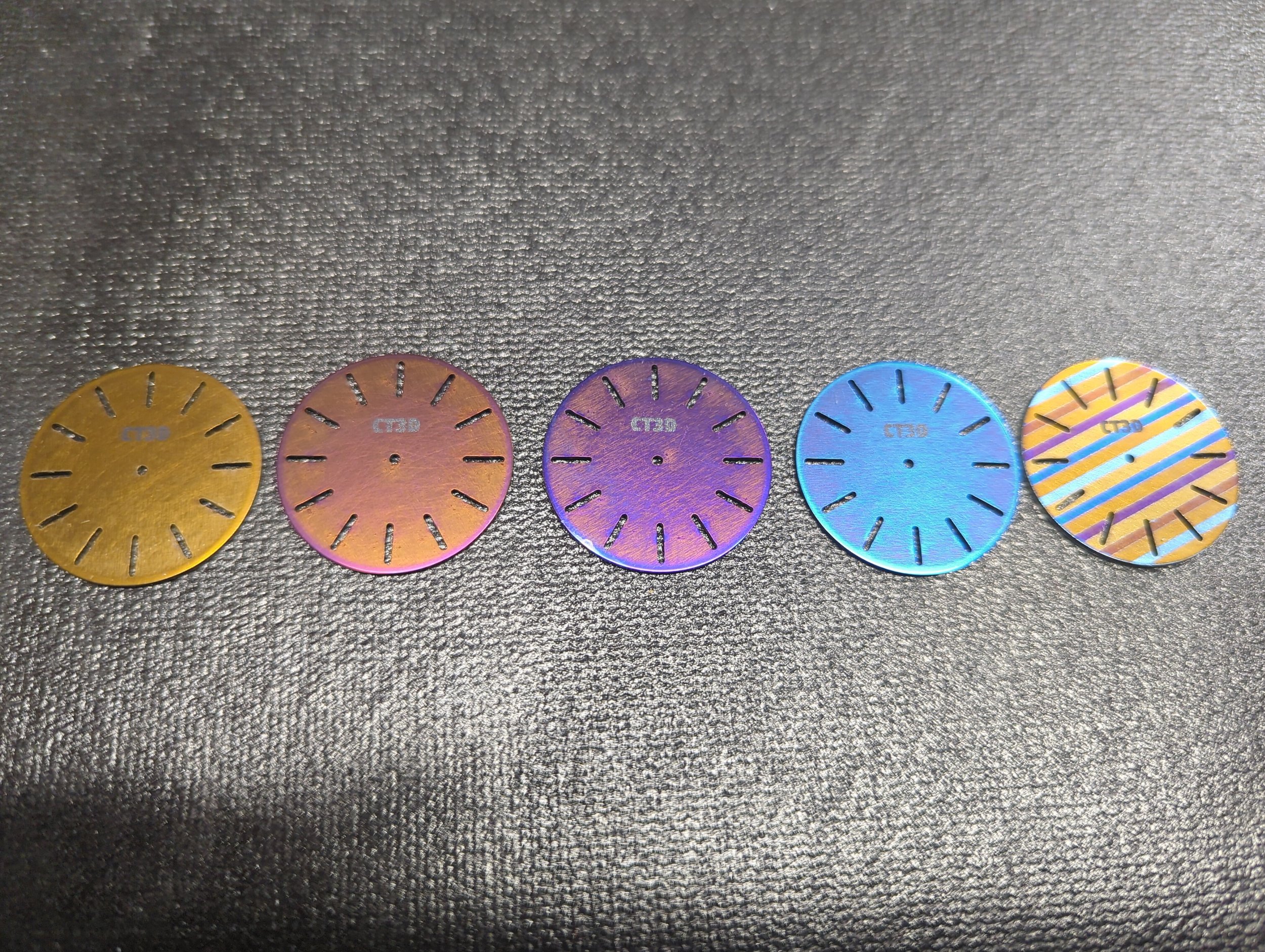

Proof of Concept: We’re bringing three products to market over the Summer 2024, with advanced products/electronics coming in Q4 2024 and Q1 2025.

Amplification: CT3D is pitching to YouTube influencers and promotional product companies to White Label products. CT3D is also performing in-person sales at events and social gatherings.

Co-Development: CT3D is actively recruiting designers, artists, Makers, and product develop companies to bring additional products to market over the coming months.

Turnkey Manufacturing: CT3D is focused on building out and streamlining it’s Turnkey Manufacturing Pipeline using the introductary products.

CT3D’s pathway to market

Spring 2024: Member of the 2024 reSET Impact Accelerator, participating in the reSET Venture Showcase in June, 2024.

Summer 2024: Launching the Turnkey Manufacturing Platform and three introductory products. Actively recruiting designers, artists, Makers, and product development companies who want to bring their ideas to life.

Fall 2024: Focusing on expanding the number of products available on the platform, streamlining the flexible factory concept, increasing quality of products produced and decreasing cost of goods sold and fabrication time.

Spring 2025: Expansion of product lines into complex assemblies, electronics including IoT and the use of the open source Home Automation platform.